Can Quartz Rods Replace Traditional Optical Materials? Next-Gen Sensor Applications Spark Debate

Let’s settle this once and for all: the optical materials industry is at a crossroads, and quartz rods are the lightning rod of controversy. While traditionalists cling to glass, polymers, and sapphire, innovators are betting on three quartz rod variants—quartz glass rods, capillary silica quartz rods, and half round quartz rods—to redefine precision sensing. Here’s why these unassuming cylinders are either the future or a fad, depending on who you ask.

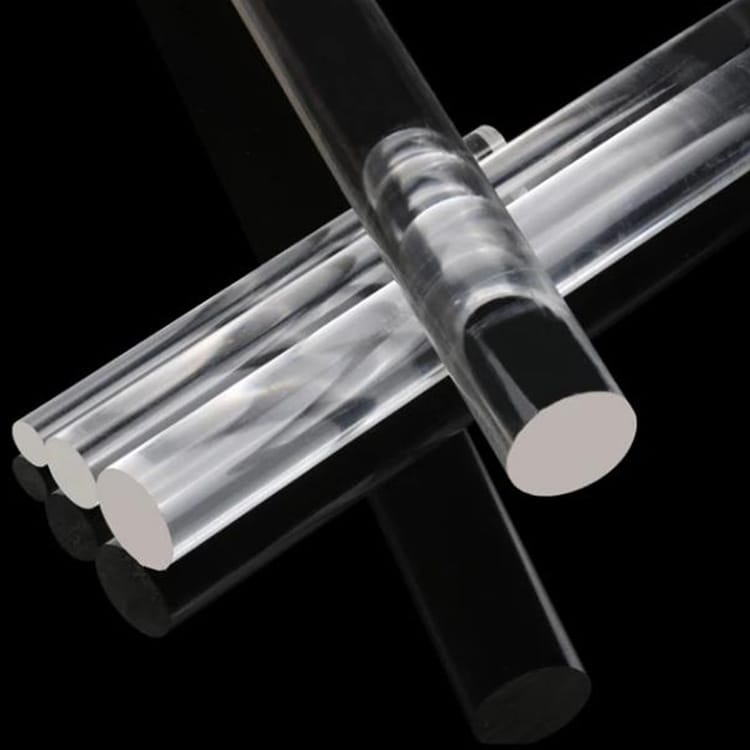

Quartz Glass Rods

Quartz Glass Rods: The Thermally Unshakable Contender

Picture a LiDAR sensor in a self-driving car melting under the Arizona sun. Traditional borosilicate glass rods warp at 500°C, but quartz glass rods? They scoff at 1,200°C while maintaining sub-micron dimensional stability. Velodyne’s latest LiDAR arrays now embed these rods to channel laser pulses in desert trials, where temperature swings from -20°C to 80°C caused traditional optics to misalign by 0.3mm—enough to misidenticate a pedestrian. Quartz eliminated that error entirely.

But here’s the kicker: their UV transparency (down to 160nm) allows next-gen biosensors to detect pathogens via fluorescence without signal loss—something polymer rods degrade after 50 cycles.

Capillary Silica Quartz Rods: The Microfluidics Game-Changer

Forget clunky pipettes. Capillary silica rods, with inner diameters as narrow as 5µm, are enabling single-cell analysis in cancer diagnostics. Illumina’s NovaSeq X sequencers now use these rods to isolate circulating tumor cells from blood samples. The result? A 40% boost in detection accuracy compared to polymer capillaries, which adsorb biomolecules and skew readings.

Critics argue they’re “too brittle.” Tell that to Roche Diagnostics, who’ve deployed these rods in handheld glucose monitors. Their chemical inertness prevents glucose oxidase degradation—a flaw that plagues stainless steel microfluidics in humid environments.

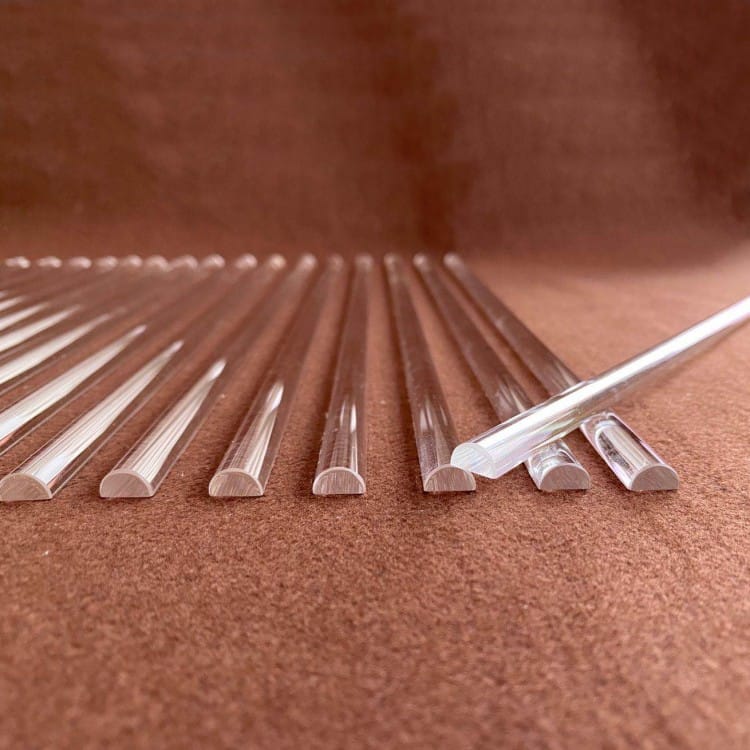

Half Round Quartz Rods

Half Round Quartz Rods: The Dark Horse of Integrated Photonics

Why force light through square pegs? Half-round quartz rods, with their curvature matching fiber optic cores, are slashing signal loss in quantum sensors. IBM’s quantum team replaced traditional cylindrical lenses with these rods in their photon-counting modules, achieving 98% coupling efficiency—up from 82% with sapphire. The secret? The half-round geometry eliminates air gaps at the fiber interface, a notorious source of scattering.

But purists rage: “Quartz lacks the refractive index tunability of specialty glasses!” True—yet in lidar and hyperspectral imaging, where broadband transparency (UV to IR) matters more than refractive tricks, quartz is unbeatable.

The Elephant in the Lab: Cost vs. Performance

Let’s not sugarcoat it: quartz rods cost 3–5× more than glass. But in mission-critical applications, that premium pays dividends. Consider SpaceX’s Starship methane sensors: after polymer rods failed under cryogenic stress, quartz variants survived 100+ launch cycles without microfractures. The math is simple: a 500quartzrodbeatsa50 glass rod that fails mid-mission and costs $2M to replace.

Verdict: Replacement Isn’t the Point—Reinvention Is

Quartz rods won’t dethrone all traditional materials, but they’re carving niches where failure isn’t an option. For high-stakes sensing—whether in autonomous vehicles, quantum computing, or point-of-care diagnostics—they’re not just alternatives; they’re inevitabilities. The debate isn’t about if quartz will dominate, but where. And for engineers pushing boundaries, that’s a revolution worth betting on.

Hongwo Quartz Products

Hongwo Quartz Products

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.