Customize various quartz bottles!

Quartz bottles are containers made of high-purity quartz glass. Their unique properties allow for many applications in various fields. The following is a detailed introduction to quartz bottles:

Material and Characteristics

Quartz bottles are mostly silicon dioxide (SiO₂). This gives them many great qualities.

High Purity: Manufacturers make the bottles from high-purity quartz glass. This ensures the product’s purity and non-contamination.

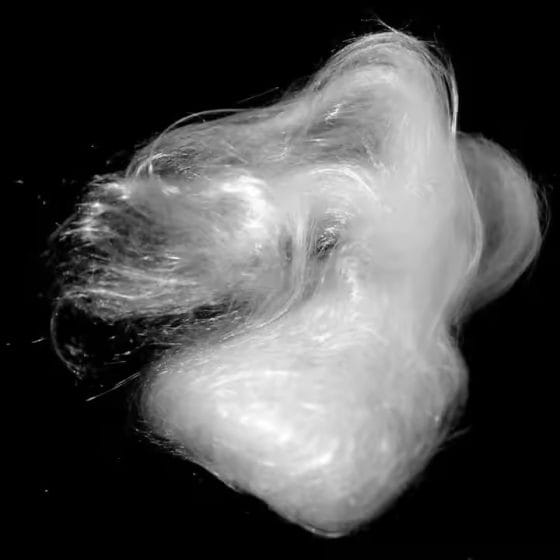

High transparency: The quartz bottles have very high transparency. They allow a clear view of the contents inside. So, they are perfect for events that must have a good display.

High Heat Resistance: Quartz bottles can withstand high-temperature treatments. They have a high melting point and good heat resistance. So, they are suitable for high-temperature environments.

Chemical Stability: Quartz bottles resist many chemicals and do not erode. They are suitable for long-term storage of various chemical products.

Application Fields

Quartz bottles are unique. They are important in many fields.

Laboratory: Quartz bottles are common in chemical experiments. They are best for preparing and measuring specific volumes, like quartz volumetric flasks. Their high precision and chemical stability ensure the reliability of experimental results.

Medical field: Quartz bottles are often used to package medicines. Their high purity and stability prevent contamination and preserve efficacy.

Chemical industry: In chemical production, quartz bottles store and transport various chemicals. They maintain the products’ stability and purity for a long time.

High-end packaging: Quartz bottles are very transparent and upscale. So, they are perfect for high-end cosmetics and perfumes.

Manufacturing Process

The process of making quartz bottles is complex and meticulous. It mainly includes these steps:

Raw material selection: We use high-purity quartz sand as the raw material. It ensures the product’s quality and purity.

Melt and form the blank: Mix quartz sand with flux. After high-temperature melting, cool the mixture to form a blank.

Tube drawing and forming: Draw the molten quartz blank into fine threads. Then, stretch, cut, and fuse them to form quartz glass tubes.

Cut the quartz glass tubes to size. Then, grind, polish, and clean them. This will make the blanks for quartz bottles.

Forming and annealing: Reheat, melt, and form the blanks of quartz bottles. Finally, cool and anneal them to make finished quartz bottles.

Quality inspection and packaging: Inspect the finished quartz bottles. Test their transparency, hardness, uniformity, and density. Ensure they meet the relevant standards before packaging and shipping.

Product advantages

Quartz bottles have the following advantages compared to other types of glass bottles:

Higher purity: Made of high-purity quartz glass, ensuring the product’s contamination-free nature.

Better transparency: Extremely high transparency, capable of clearly displaying the items inside.

Greater heat resistance: It can withstand high-temperature sterilization and other treatments. It is suitable for various high-temperature environments.

Higher chemical stability: It is stable against many chemicals. It is suitable for long-term storage of chemical products.

Hongwo Quartz Products

Hongwo Quartz Products

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.