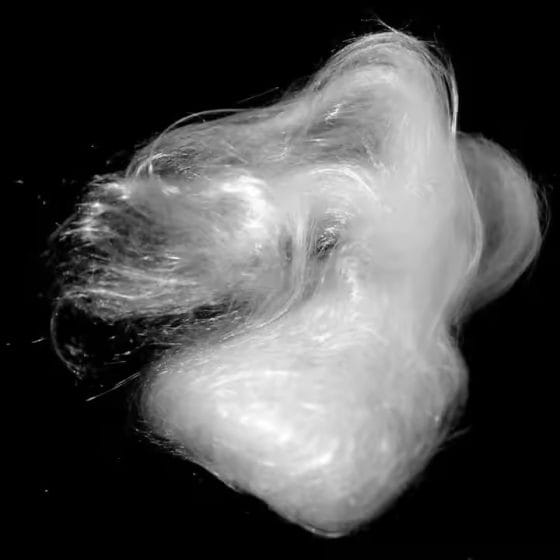

Quartz crucibles are vessels made mainly of quartz sand.

This vessel has many advantages. It is highly pure, heat-resistant, and large. It is also very precise, energy-efficient, and has good heat retention. Its quality is stable. So, it is being used more widely. Inspecting quartz crucibles is very important. It is developing towards on-site inspection.

1. You can use quartz crucibles at temperatures below 1450 degrees. They are either transparent or opaque. The electric arc method makes semi-transparent quartz crucibles. They are vital for making large-diameter single crystal silicon. They are also key to developing large-scale integrated circuits. Today, developed countries in the semiconductor industry use these crucibles. They have replaced small, transparent quartz ones. Quartz Glass Crucibles are pure, heat-resistant, large, precise, and energy-saving. They have good heat retention and stable quality.

2. They cannot come into contact with HF. At high temperatures, they react easily with caustic alkalis and alkali metal carbonates.

3. Use quartz crucibles to melt samples with K2S2O7 and KHSO4 as fluxes. They are also suitable for processing samples with Na2S2O7 (dried at 212 degrees) as a flux.

4. Quartz is brittle and easy to break. Be careful when using it.

5. You can use ordinary dilute inorganic acids as cleaning solutions, except for HF.

In China, 18- and 20-inch quartz crucibles are common for making single crystal silicon. Some manufacturers also use 22-inch and larger crucibles. The production technology of quartz crucibles from major domestic manufacturers is relatively mature. They import the production’s raw materials, quartz sand, from the U.S. and high-purity quartz sand from Norway.

Process flow:

1. High-purity quartz sand

2. High-purity graphite mold

3. Vacuum loading and forming

4. Vacuum electric arc melting

5. Natural cooling and de-molding

6. Initial inspection of quartz crucibles.

7. Cold working: sandblasting, cutting, chamfering.

8. Secondary inspection of quartz crucibles

9. Ultra-clean cleaning, ultrasonic cleaning, high-pressure spray cleaning, automatic drying. Heating and baking, spraying.

10. Tertiary inspection of quartz crucibles

11. Vacuum packaging

12. Finished product storage

Quartz Glass Crucibles

Quartz Glass Crucibles

Hongwo Quartz Products

Hongwo Quartz Products

Scan the QR Code to start a WhatsApp chat with us.