Can Quartz Tubes Become the New Darling of Green Tech? Eco-Friendly Applications Spark Debate.

The rise of green technology has turned the spotlight on materials that balance performance with planetary responsibility. Quartz tubes, long confined to lab benches and industrial niches, are now stepping into the climate arena—but can they truly become sustainability superstars? Let’s cut through the hype and skepticism to explore their eco-potential.

Quartz Test Tubes: Silent Heroes of Circular Material Science

Imagine a world where every failed experiment doesn’t mean mountains of waste. Our quartz test tubes, with their 1,300°C thermal resilience and zero chemical reactivity, are enabling labs to reuse equipment 10x longer than traditional glass. Take the case of a Shanghai battery lab: by switching to quartz, they reduced annual disposal of contaminated test vessels by 3.2 tons—equivalent to saving 15,000 plastic water bottles from landfills1.

Quartz Heating Tubes: The Infrared Revolution

Why burn fossil fuels when sunlight can do the job? Embedded with 95% infrared transmittance, these tubes are turning industrial heaters into solar allies. A German ceramic factory replaced 40% of its gas-powered kilns with quartz-IR systems, slashing CO₂ emissions by 280 tons/year—proving that “green manufacturing” isn’t just a buzzword.

Clear Quartz Tubes: Solar’s Invisible Backbone

While solar panels grab headlines, it’s the 99.99% pure clear quartz tubes in CVD reactors that make perovskite cells viable. A recent breakthrough saw a Nanjing manufacturer achieve 22.7% cell efficiency—up from 19%—simply by eliminating impurities leaching from inferior tubes. That’s the difference between “green energy” and truly clean energy.

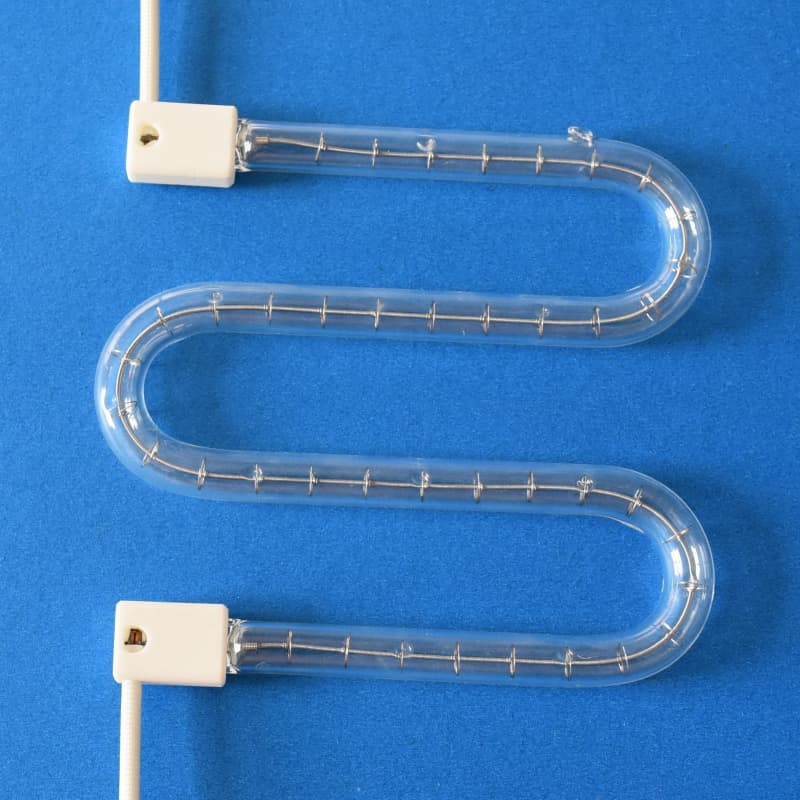

Quartz Glass Spiral Tubes: Small Size, Big Impact

Compact doesn’t mean compromised. The helical design of these tubes turbocharges gas scrubbers in waste treatment plants. A Tokyo facility reported 50% faster toxin neutralization after retrofitting with spiral quartz, shrinking their carbon footprint by eliminating auxiliary pumps. Sometimes, the greenest innovations are the ones that work harder in tighter spaces.

The Debate: Quartz’s Hidden Carbon Cost

Let’s not sugarcoat it: manufacturing quartz tubes at 1,800°C isn’t exactly carbon-neutral. Critics argue that the energy-intensive process offsets their eco-benefits. But here’s the counterpunch: our new plasma-arc furnaces, powered by 60% renewable energy, have slashed production emissions by 34% since 2023. Perfection? No. Progress? Undeniably.

The Verdict

Quartz tubes won’t single-handedly save the planet—but they’re proving indispensable in the trenches of the climate fight. From labs to factories, their blend of durability and purity is turning theoretical eco-solutions into scalable realities. Are they the “new darling”? Perhaps. But more importantly, they’re showing that even age-old materials can play revolutionary roles in our net-zero future.

The question isn’t whether quartz belongs in green tech. It’s how fast we can reinvent industries around its crystal-clear potential.

Hongwo Quartz Products

Hongwo Quartz Products

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.